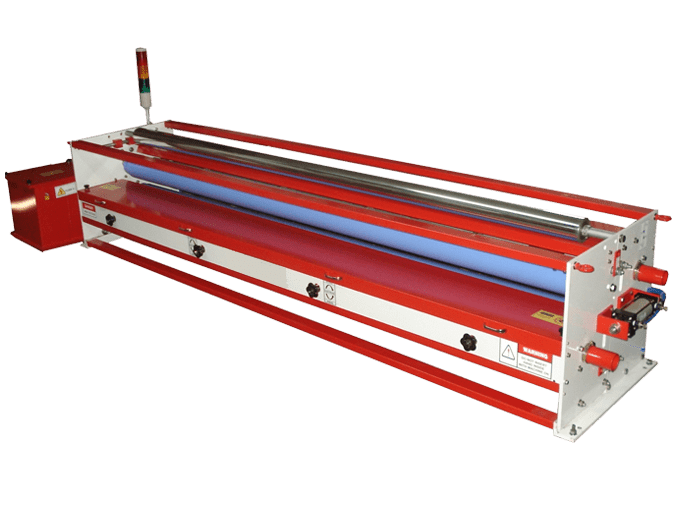

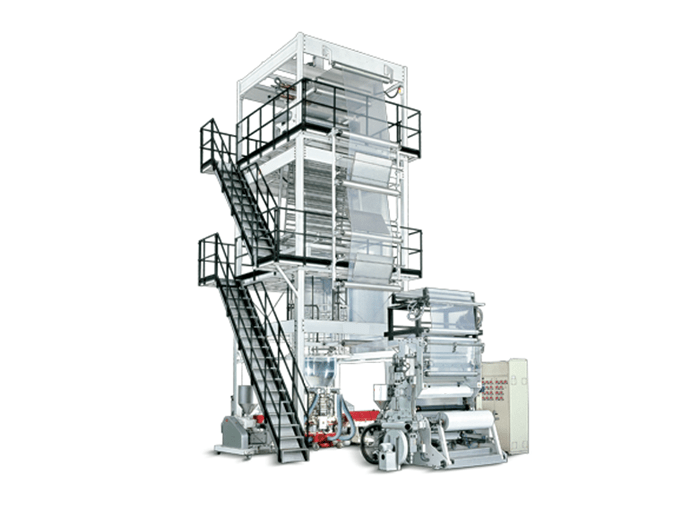

Corona treater on blown film or cast film extrusion lines is essential in order to obtain a perfect surface tension prior to the following converting process like printing/lamination/coating etc. . Without pretreatment the extruded substrates will not allow further converting processes due to low surface tension.

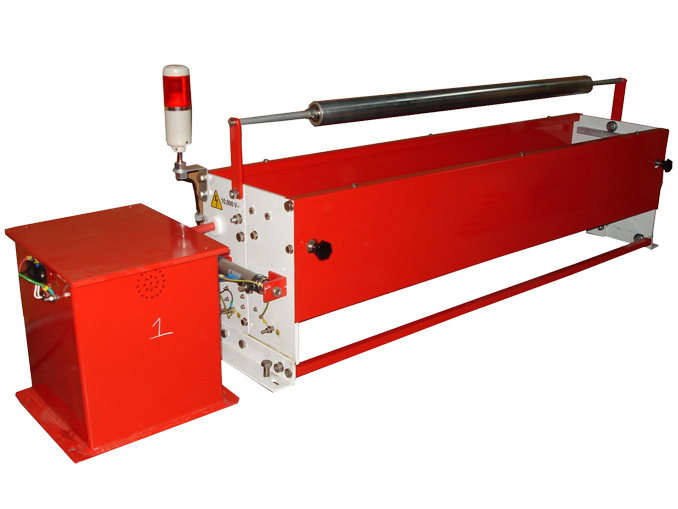

As a film manufacture you require reliable Corona treatment equipments that can easily be maintained, be segment set-up and run production nonstop. These are key-points for a Corona treater on an extrusion line. The Electro Tech Inc. Corona treaters are designed for our customers with the customer’s challenges in mind. We focus on equipments that will make your production run smoothly with uniform dyne level and no unplanned stops.

The Electro Tech Inc. Corona treaters for extrusion line will provide higher dyne level on your materials due to the combination of ultra-efficient generators and superior treatment station design. The advanced electrode design eliminates fluctuations in dyne levels across the web width and furthermore guarantees no undesirable backside treatment.

The Electro Tech Inc. treater stations are all made with the unique Quick Change system that allows the operators to perform segment set-up and maintenance within minutes – thereby providing maximum production time for your extrusion line.

Specifications

- Width : 400mm-4000mm

- Speed : 1- 200 mtr./min

- Electrodes : Aluminum / Stainless Steel

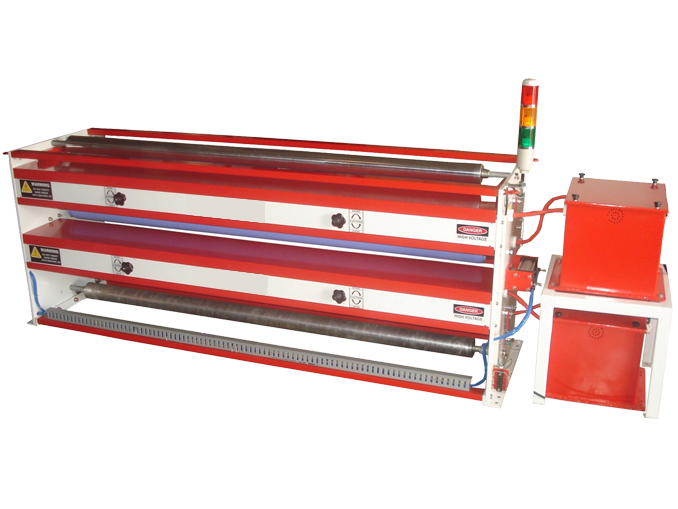

- No of Sides for Treatment : 1.2.4

- Electrode Type: Segmented / Tubes / Strip Type.

- Roll covering : Silicone Sleeve

- Roller Dia : 50mm-200mm

- Types of Extrusion : Blown / Cast/ Stretch / Sheet

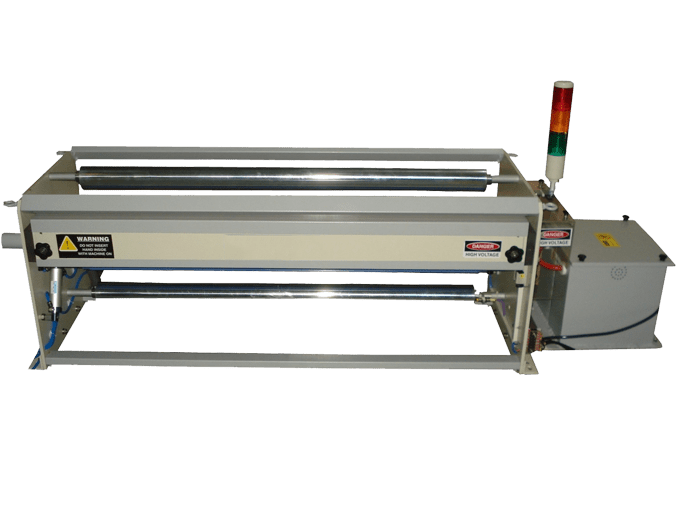

Optional Features

- Silicon or Ceramic-coated Treater Rollers

- Stainless steel rod type fixed electrodes

- Air gap adjusters with digital readout

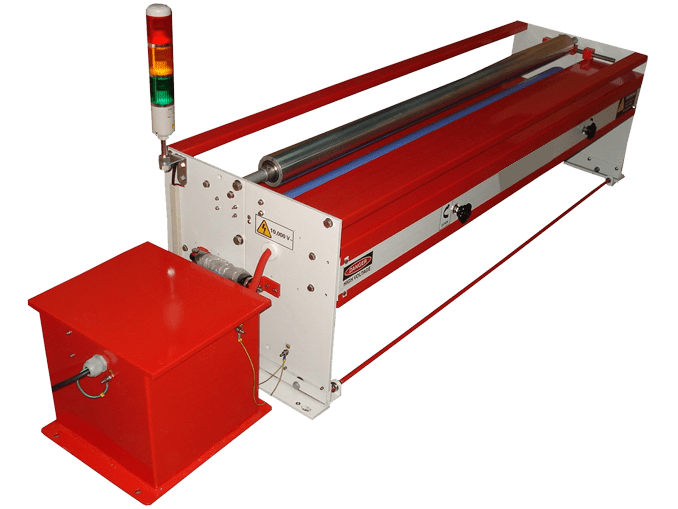

Salient Features

- Corona Treater Rollers covered with high dielectric grade silicone sleeves

- Pneumatically actuated treating heads / Split Assembly for easy threading of the films.

- 1dler rollers at film entry & exit to ensure proper wrap angle of film with treater roller.

- Easy Inline air gap adjustment with knobs provided externally on the ducts

- S.S. Braided double dielectric sheathed high tension cable to ensure safety

- Dynamically and statically balanced rollers.

- Proximity switch for zero speed sensing & closed loop feedback for Auto watt density control.

- Assembly open safety switch for human safety

- Rigid cross members and electrode holding bars to ensure uniform and parallel air gaps